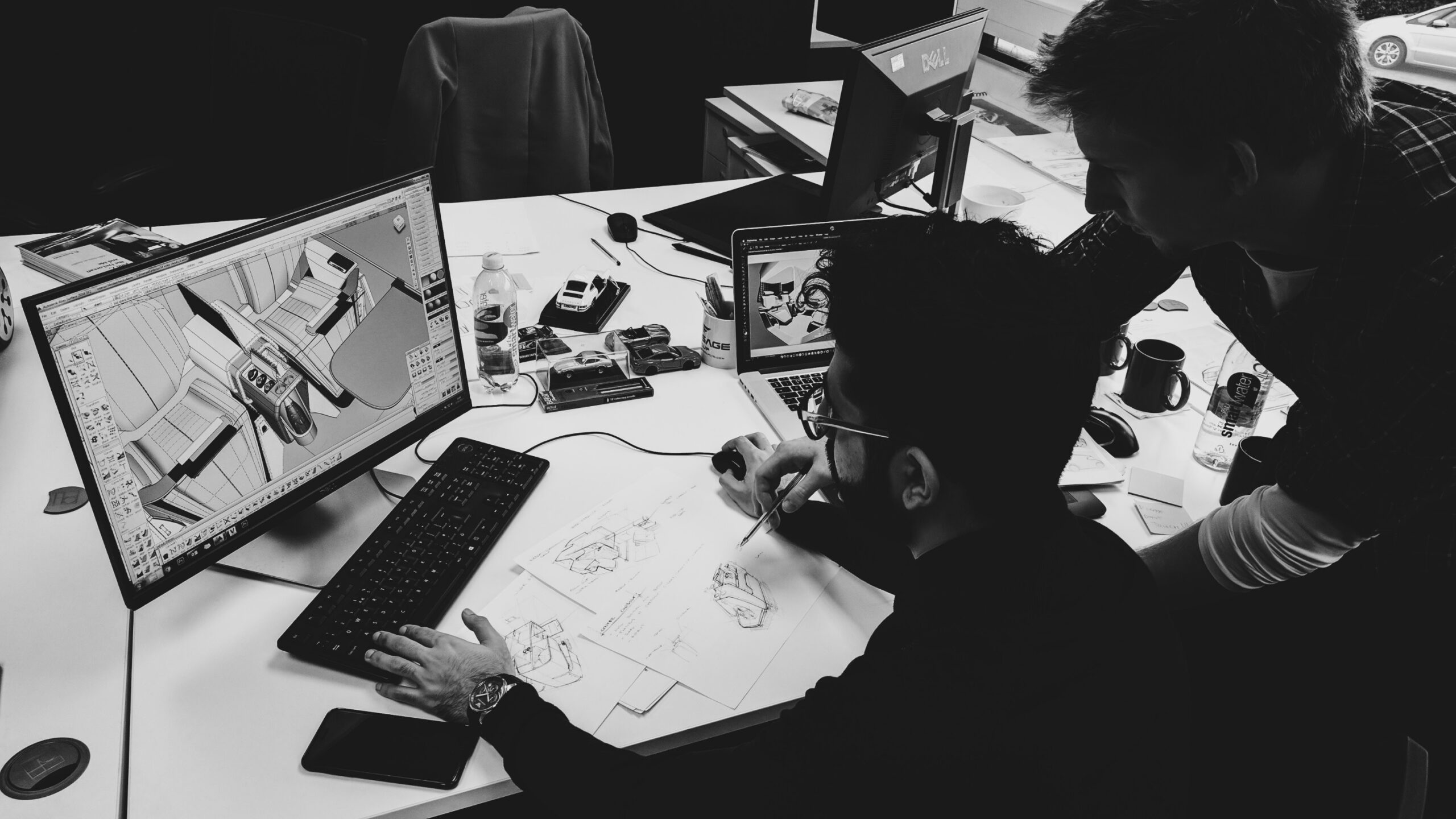

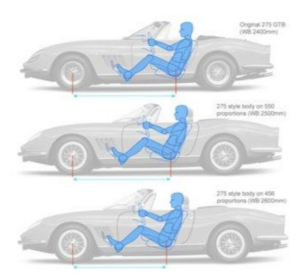

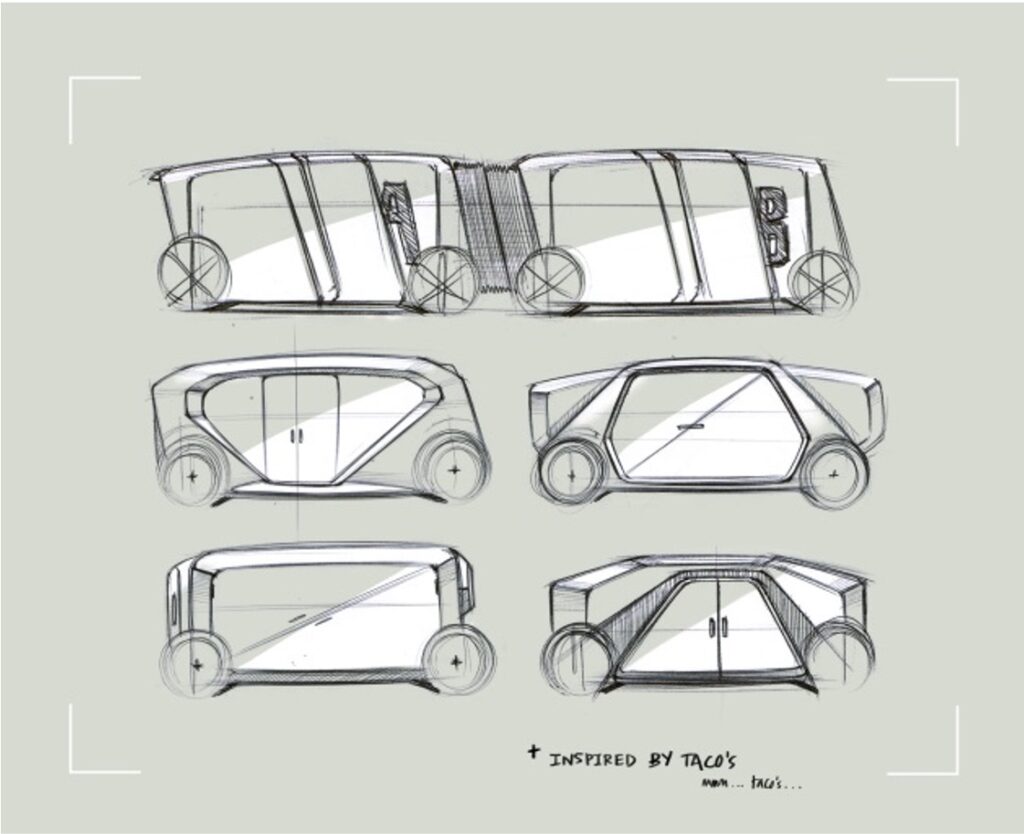

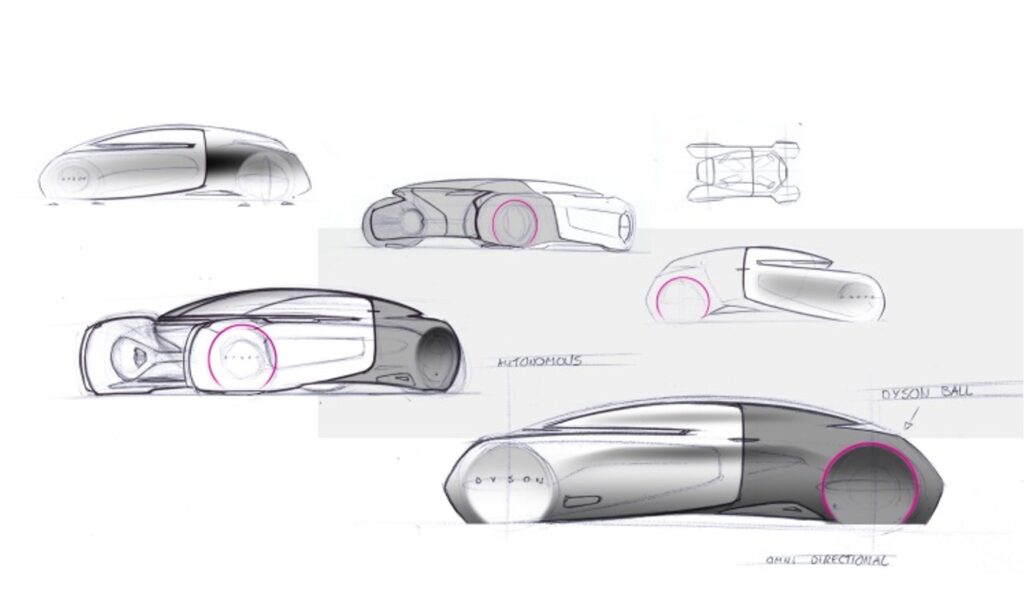

Concept, packaging and visual representation

Offering creative design support for concept, packaging, and visual representation for anything you can see or touch for the interior or exterior of a vehicle, fuselage, show pod or model plus associated mechanisms. We believe the key to great design is found between the connection of technology and art. We push ourselves to be progressive, using cutting edge technology to deliver experimental design services.

Find out more