Soft trim and foam skiving development

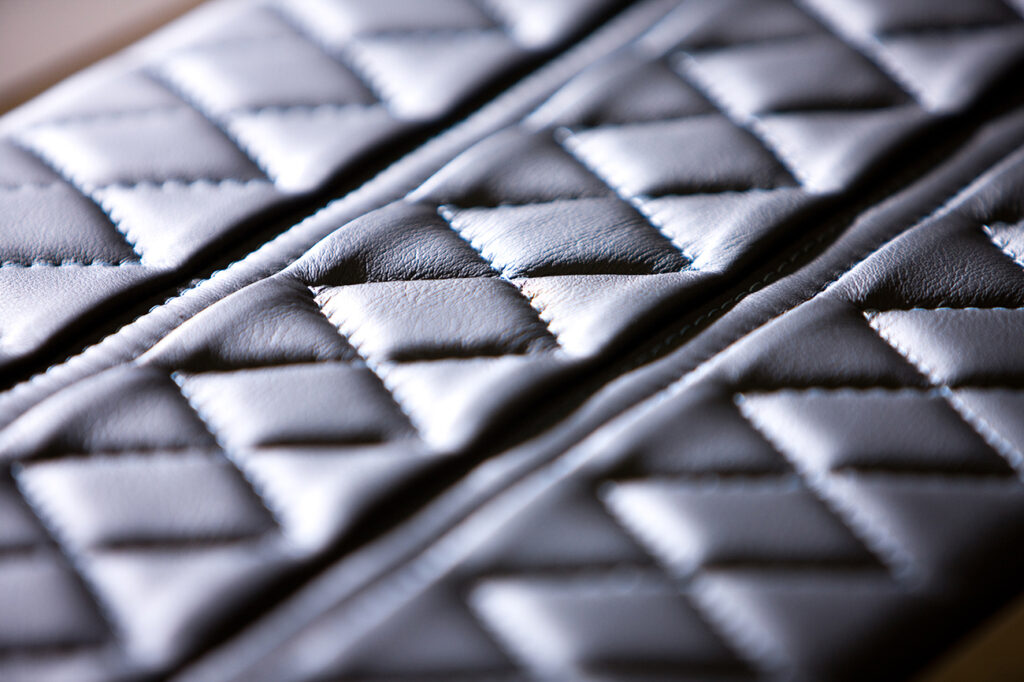

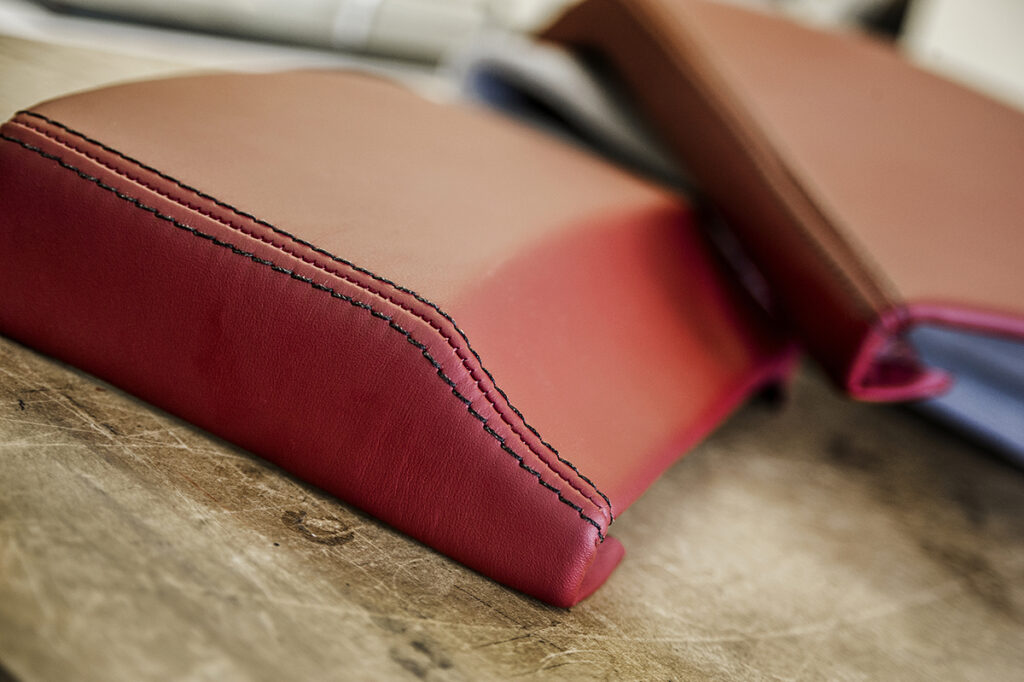

Our bench trimmers have been trained to a high level, working with new production parts and classic vehicle trimming. Developing foam to the customers specification from a one-to-one CAD plot drawing to deliver high end seat finish.