About Us

Envisage Group was established in 2009 with 3 sites in Coventry, UK, and an international footprint in the USA, a leading supplier of concept design, realisation, and engineering services.

The Group incorporates Envisage Concept Design & Engineering and Envisage Technologies, our clients range from the largest and most prestigious OEMs and product manufacturers to start-ups and high net worth individuals. In addition to its design and engineering divisions, the Group also incorporates Envisage Recruitment, a specialist recruitment consultancy.

Working closely with their clients, Envisage offer both design and realisation expertise from concepts, to test public reaction, through to the detailed engineering that ensures a programme delivers the right product. Thanks to a unique set of skills, the business can even build low volume runs of fully engineered vehicles and products.

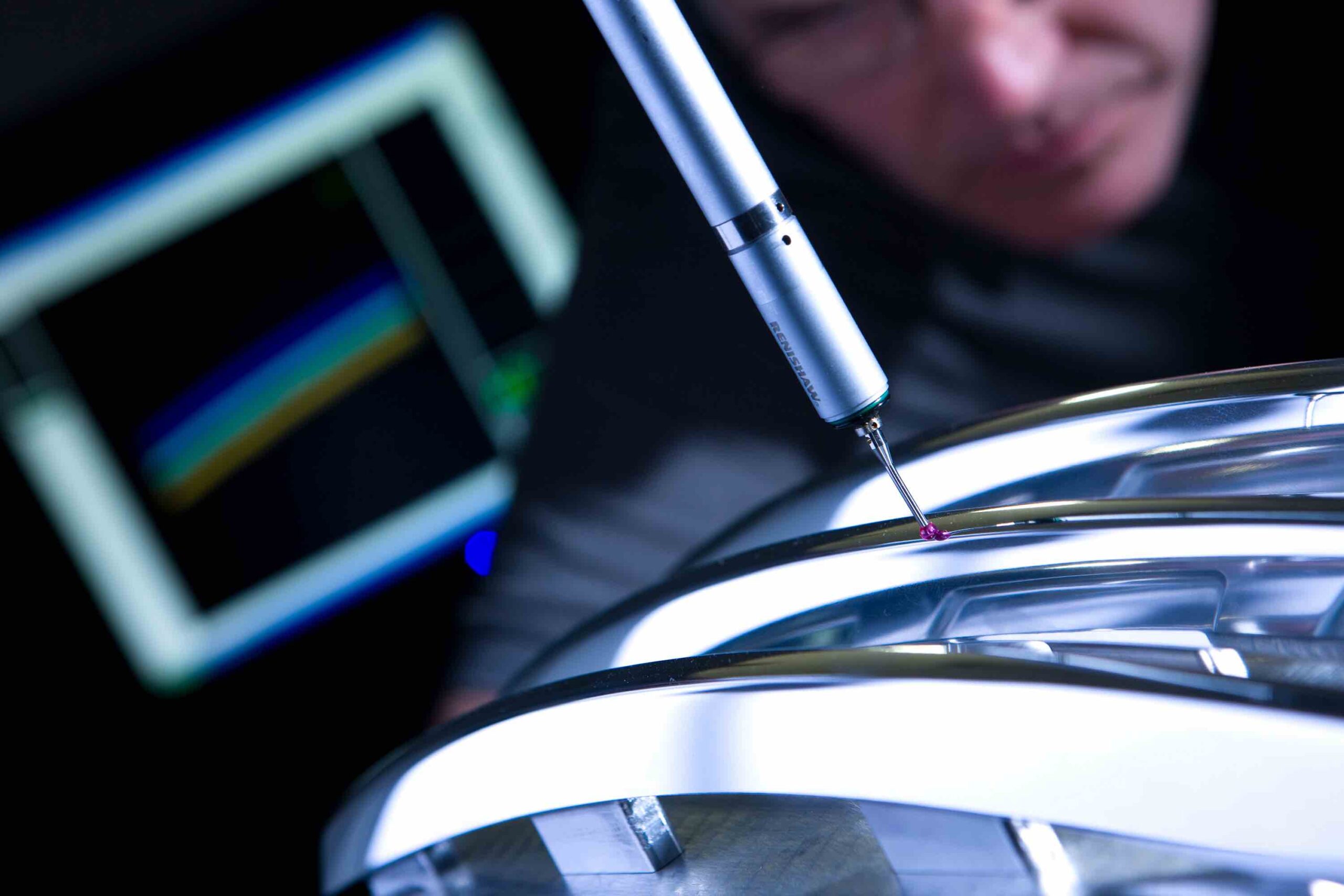

We are made up of a vast range of skillsets from design to production. Our talented team enable us to realise our clients’ visions and implement innovative materials and finishes into high quality products and prototypes.

With a global reputation for engineering expertise and craftsmanship, and for the exceptional quality of its services. Although most of our work is within the automotive industry, we also operated within, aerospace, marine, the wider mobility market, and other manufacturing industries.

We are ISO 14001:2015 and ISO 9001:2015 Certified

Download our Certifications here

-

![]()

Tender for Quotes [PDF]

Envisage Technologies Ltd are looking for a contractor(s)/suppliers to carry out works on our premises based in Coventry.

-

![]()

ISO 14001:2015 Certificate [PDF]

Certification for Environmental Management System which has been assessed and conforms to ISO 1400:2015

-

![]()

ISO 9001:2015 Certificate [PDF]

Certification for Quality Management System which has been assessed as conforming to ISO 9001:2015